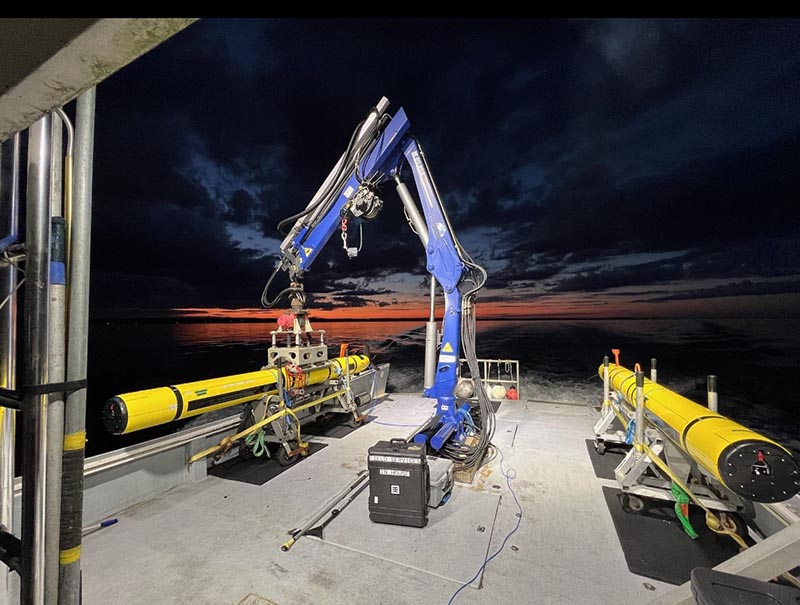

Operating in the Arctic is not for the faint of heart. It’s cold, remote, and unforgiving. Every piece of equipment on board must perform under extreme stress, including your ship crane. Choosing the right ship crane for Arctic operations goes beyond basic specs—it’s about selecting a tool built for survival, safety, and reliability in some of the world’s most demanding conditions.

Let’s take a look at what matters when picking a crane that can handle the challenges of Arctic work, from frigid temperatures and icy decks to isolation and strict compliance regulations.

Arctic Conditions Demand Tough Equipment

The Arctic isn’t just chilly—it’s one of the harshest environments on the planet. Temperatures can plummet to -40°C (-40°F), ice buildup is constant, and machinery failure in these conditions can put your entire crew at risk. In these temperatures, traditional materials and systems simply don’t hold up.

According to the U.S. Energy Information Administration, the Arctic is believed to hold around 13% of the world’s undiscovered oil and 30% of its untapped natural gas. That’s a massive opportunity—but only if you’re equipped to reach it. Your marine cranes need to be ready to face that challenge head-on.

Cold Climate Cranes: Built for the Freeze

Standard cranes just aren’t cut out for this kind of work. You need cold climate cranes—equipment engineered specifically to perform in freezing temperatures. These cranes are designed with specialized materials that won’t crack in the cold and hydraulics that remain fluid in extreme conditions.

Standard lubricants can freeze or thicken, making a crane sluggish and difficult to operate. But with Arctic-rated seals and fluids, cold climate cranes can continue working smoothly even when everything else is frozen solid.

Operator safety is also a key consideration. Heated, enclosed cabins are a must in these environments. Not only do they protect the person at the controls, but they also allow for safer, more precise operation when visibility is low or conditions are icy.

Fighting Corrosion in the Ice and Salt

Saltwater and freezing temperatures create the perfect storm for corrosion. Rust and wear can destroy mechanical systems in a short period of time, especially if the equipment isn’t designed to withstand constant exposure to both ice and salt. That’s why marine cranes used in Arctic operations must have extra layers of protection.

Materials like stainless steel or galvanized components are often used, and epoxy coatings help protect vulnerable parts. On top of that, electrical systems need to be fully sealed to avoid saltwater damage, and hydraulic lines must be reinforced to resist cracking or corrosion. The more durable your crane, the longer it will last—and the safer your team will be.

Reliability in the Middle of Nowhere

One major challenge of working in the Arctic is that help is often hundreds, if not thousands, of miles away. There are no nearby repair shops or overnight shipping options for replacement parts. That’s why reliability is critical. When choosing a ship crane for Arctic operations, you need something that can stand up to wear and tear, operate for extended periods, and be easily maintained on board.

Crane systems with modular designs make part replacements quicker and easier, which is important when working in remote regions. Remote monitoring systems are also becoming more common, allowing crews to catch small problems before they become big ones. And let’s not forget simplicity—straightforward controls and familiar systems reduce the need for intense training, especially important when operating in high-risk conditions.

Lifting Power Isn’t the Whole Picture

Yes, lifting capacity matters—but how the crane lifts is equally important in the Arctic. Cranes used in polar regions must provide steady, precise lifting even in rough seas. Load stability systems help with this, especially when the wind picks up or the vessel is rolling. Active heave compensation can also be a huge asset, especially for offshore support vessels dealing with dynamic movement.

Think about your mission. Is your crane going to be used for offshore oil and gas support? Scientific missions? Cargo transport? A cold climate crane should be tailored to your specific application, not just a one-size-fits-all solution.

Safety Above All

Arctic operations are full of hazards. Ice on the deck, blizzards that limit visibility and freezing equipment are just a few of the risks. That’s why crane safety features are so important. Heated cabins, anti-icing systems on booms and lines, and integrated lighting help protect both the operator and crew during critical lifts.

A good crane should also include manual overrides in case of a power failure. If something goes wrong in the Arctic, your team needs to be able to regain control quickly and safely.

Don’t Skip Compliance

Operating in polar waters comes with regulations. Your ship crane for Arctic operations should meet industry standards and maritime codes specific to cold-weather use. That includes compliance with the IMO Polar Code and certifications from bodies like ABS, DNV, or Lloyd’s Register for Arctic service. Choosing a crane that’s already certified can speed up inspections and save you from regulatory headaches down the line.

Long-Term Thinking Saves Money

It might be tempting to go with the most affordable crane option up front, but in the Arctic, that could cost you much more over time. Breakdowns are expensive, downtime can delay your mission, and replacement parts aren’t always easy to come by.

Instead, consider the full lifecycle cost of your crane. How often does it need service? What’s the track record of the manufacturer in cold-climate operations? Will it hold up over a 10- or 15-year lifespan in harsh environments? Spending more on a durable, Arctic-tested crane can save you from costly repairs and interruptions later on.

Choose the Right Partner

Finally, who you buy your crane from is just as important as the crane itself. Not all manufacturers are experienced in Arctic operations. Look for a partner who knows the environment and has a history of delivering marine cranes for cold-weather use.

A great supplier will offer more than just a crane—they’ll provide expert guidance, custom designs when needed, and responsive support no matter where your vessel is operating.

At DMW Marine Group, for example, every crane is engineered to meet the specific demands of the customer and the mission. From compact knuckle booms to heavy-duty offshore cranes, their systems are built to last—even in the most extreme conditions.

Choosing the right ship crane for Arctic operations is about far more than lifting capacity. You need a crane that can handle extreme cold, fight off corrosion, operate safely in poor conditions, and keep running when you’re hundreds of miles from help.

By focusing on cold-weather engineering, long-term durability, and expert support, you’ll get more than just a crane—you’ll get peace of mind. The Arctic might be a brutal place to work, but with the right tools, it doesn’t have to be impossible.

Need a marine crane built for the Arctic? DMW Marine Group designs reliable, rugged cold climate cranes made for the world’s toughest conditions.

Contact us to explore our Arctic-ready cranes or get in touch today to talk to a specialist.